The Rise of LFP Batteries: A Game-Changer in Sustainable Energy

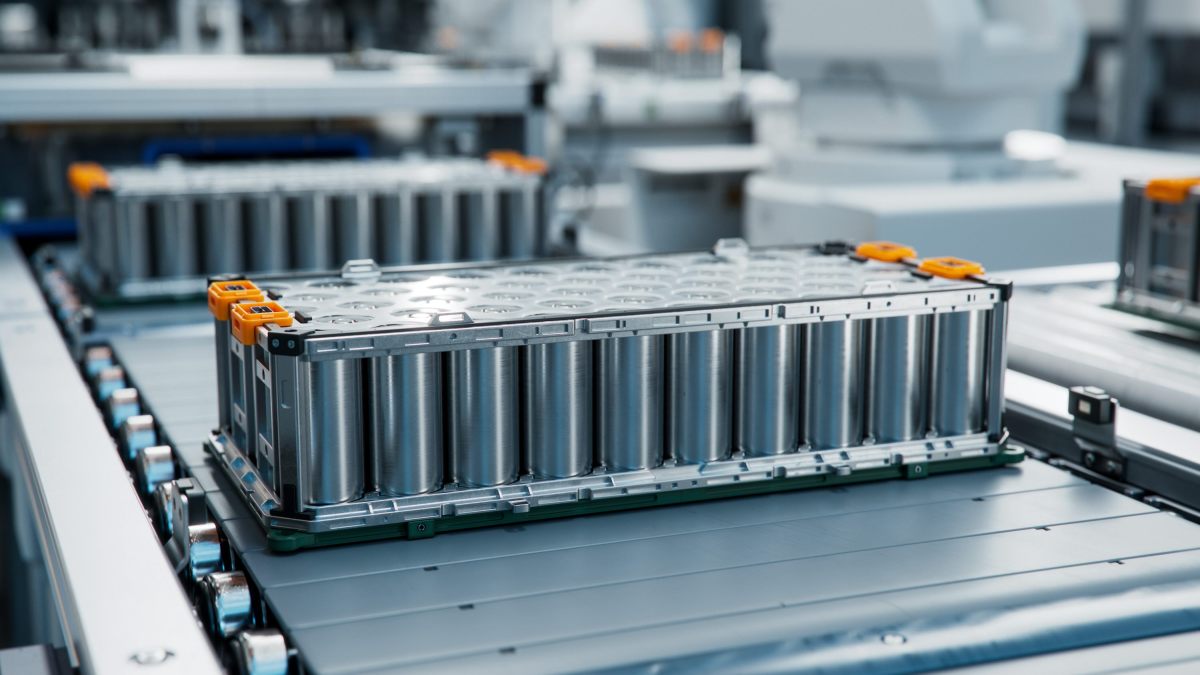

In the ever-evolving landscape of clean energy, lithium-iron-phosphate (LFP) batteries are emerging as a beacon of hope for a more sustainable future. Their affordability and durability make them a crucial component in the transition to electric vehicles (EVs) and renewable energy storage. However, the production of LFP batteries is currently dominated by China, posing significant challenges for American automakers grappling with tariffs and regulatory hurdles. Enter Electroflow, a startup poised to revolutionize the industry with an innovative approach that could reshape the global supply chain.

The Rise of LFP Batteries

LFP batteries have gained prominence due to their cost-effectiveness and longevity, offering a practical solution for industries seeking to reduce their environmental footprint. As the world accelerates its shift towards green energy, the demand for these batteries is skyrocketing, making their production a critical focus area. The challenge lies in the dominance of Chinese manufacturers, who currently produce 99% of the world’s LFP supplies, creating a bottleneck for companies outside China aiming to adopt this technology.

The Challenge of Supply Chain Dependency

The reliance on Chinese production is a double-edged sword. While it has driven down costs globally, it also poses strategic and economic risks for other countries. U.S. automakers face elevated costs due to tariffs and logistical complexities, hindering their ability to compete effectively. This dependency underscores the urgent need for domestic innovation to establish a self-reliant supply chain.

Electroflow’s Breakthrough Technology

Electroflow, a forward-thinking startup, has developed a groundbreaking method to produce LFP batteries, significantly simplifying the traditional ten-step production process into just three. This innovative approach not only reduces costs but also enhances efficiency, aiming to undercut Chinese prices by up to 20%. By leveraging electrochemical cell technology, Electroflow’s system extracts lithium from brine with remarkable efficiency, demonstrating its efficacy in a California geothermal site.

The Cost and Environmental Benefits

The cost-effectiveness of Electroflow’s technology is a game-changer. Projected to reduce production expenses by 40% compared to current U.S. costs, their system could lower the price of LFP batteries to under $2,500 per metric ton. Furthermore, the process is environmentally friendly, requiring minimal electricity and water, with most of the latter being recyclable. This sustainable approach aligns perfectly with global objectives to minimize ecological impact.

A Scalable and Modular Solution

Electroflow’s modular design, deployable in a 20-foot shipping container, offers scalability and versatility. Capable of producing 100 metric tons annually, this system can be replicated across various sites, enabling widespread adoption without excessive infrastructure investment. This modularity not only enhances production capacity but also ensures efficiency, making it an attractive solution for industries looking to adopt sustainable practices.

Conclusion: Paving the Way for a Sustainable Future

Electroflow’s innovative technology signifies a pivotal moment in the clean energy revolution. By addressing the challenges of cost and supply chain dependency, they are paving the way for a more sustainable and self-reliant future. Their approach has the potential to empower U.S. automakers to compete on a global scale, driving the adoption of EVs and supporting the transition to renewable energy. As the world continues to prioritize sustainability, Electroflow’s breakthrough stands as a testament to innovation’s role in overcoming adversity and fostering a greener tomorrow.

No Comments